The production of the EV cleaning system is based in one of the largest steam cleaner factories in Italy, with more than 40 years of experience. All products of E V International are made under strict quality control.

Qualified personnel who work with high-quality materials to achieve the best possible results. Modern technology and precise performance can be seen in the design of the device. The digital display, the shape of the body and the material from which it is made are state-of-the-art.

Excellence of Execution

Dry Steam – Blue Steam

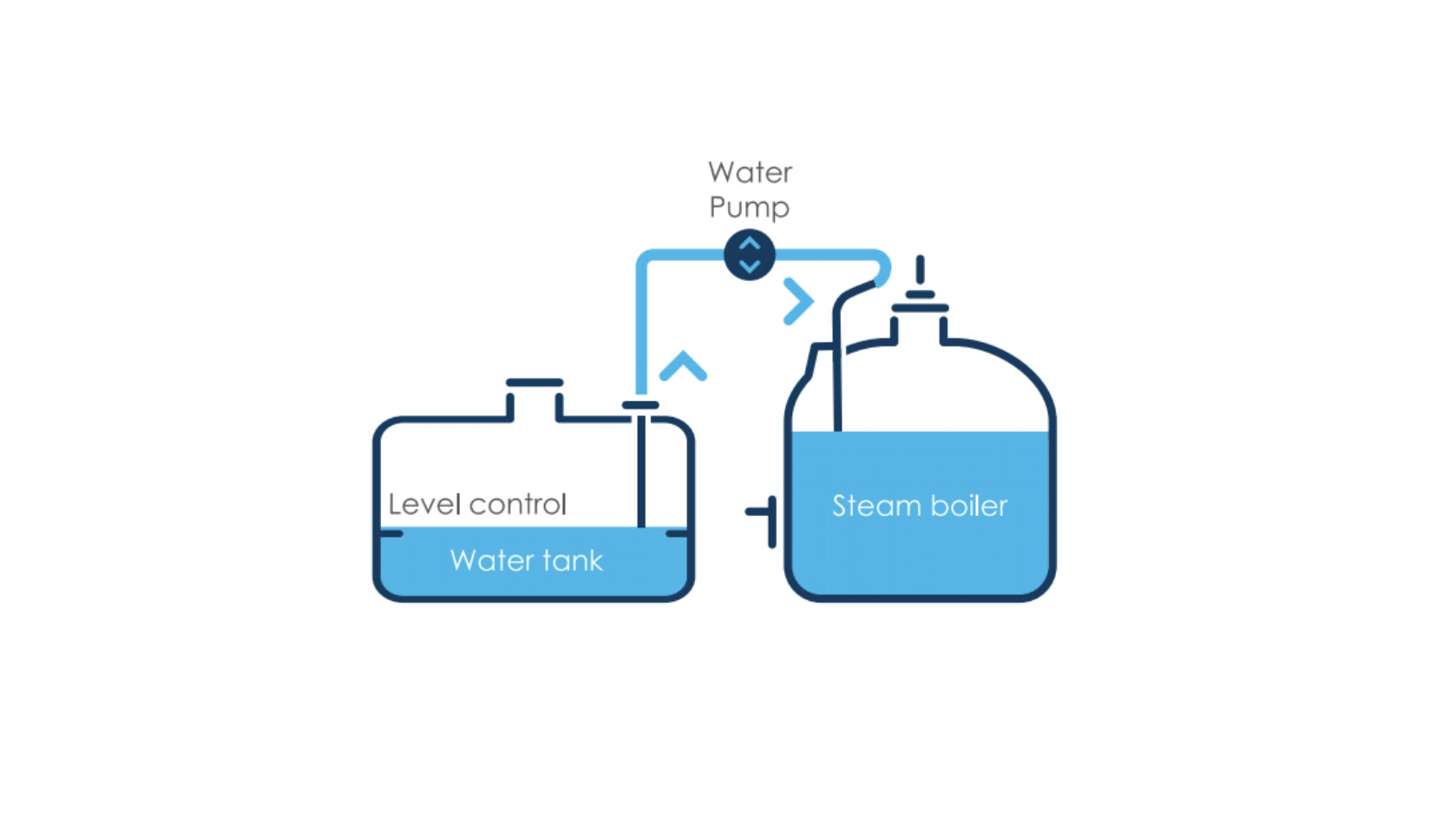

Steam quality depends of the proper water/steam ratio in the boiler. The water probe is designed to provide the best steam quality.

Steam itself is formed by heating water above 100 °C (212 °F). While using it for cleaning, however, a distinction shall be made between the different types of steam and the respective amount of humidity that they contain.

- From 100 °C (212 °F) to 130 °C (266 °F) – gray steam or steam with high humidity content (up to 80%)

- From 130 °C (266 °F) to 150 °C (302 °F) – white steam or steam with a predominant humidity content (between 50% and 20%)

- From 150 °C (302 °F) to 170 °C (340 °F) – blue steam (or dry steam) with a minimum humidity content (≤ 5%)

Using dry steam, the EV cleaning system can operate on almost all surfaces without damaging them. Besides the water heating temperature, the shape of the boiler itself is very important as well. The specially designed steam dome at the top of EV’s boiler makes it possible to store a very large amount of dry steam ready for use. The other advantage of the dome is that the steam is drawn from its uppermost part, where it is impossible to retain water. This eliminates the probability of water spraying out of the steam nozzle during the operation.